The pandemic highlighted the risk of an extended or concentrated supply chain, causing many organisations to reassess their strategy. So how are organisations innovating and de-risking their supply chain systems? Let’s explore this.

So how will organisations continue to de-risk their supply chain?

Just-in-time vs just-in-case models

Organisations have spent billions of dollars over many years to optimise their supply chains to enable the just-in-time inventory model whilst also reducing the number of suppliers. The stock flow disruptions from the pandemic forced a lot of businesses to revert back to the just-in-case inventory model.

Fast forward to today, organisations are seeing the benefits of combining the just-in-time with the just-in-case models. It de-risks their supply chain, optimises the working capital and reduces erosion of margins. The balance is the key.

Some key questions to consider:

- Are organisations applying economic modelling to balance local product sourcing cost vs the reducing global shipping costs?

- Are economic models being used to forecast disaster recovery plans?

- Can organisations increase volume orders with suppliers upon request with their current supply chain?

Customer focused supply chain: Demand sensing and planning

Utilise advanced analytics and demand sensing technologies to gain real-time insights into customer behaviour and demand patterns. By collecting and analysing data from various sources such as; point-of-sale systems, zero party CRM data, marketing and sales data, you can better understand customer preferences, anticipate demand fluctuations, and align your supply chain accordingly.

Customer focused supply chain: Omni-channel integration

Seamlessly integrate different sales channels, such as brick-and-mortar stores, e-commerce platforms, mobile apps, and social media, to provide a consistent and cohesive customer experience. Enable customers to interact, purchase, and receive products through multiple channels of their choice while maintaining visibility and coordination across the entire supply chain.

Customer focused supply chain: Deploying collaboration platforms

Organisations are implementing collaborative platforms that connect customers, suppliers, and other partners in the supply chain ecosystem. These platforms facilitate real-time information sharing, communication, and collaboration, allowing for faster response to customer needs, improved order visibility, and increased transparency across the supply chain.

How did Australian mining companies de-risk their supply chain?

During the pandemic, Paul Mitchell, Ernst and Young’s global mining and metals leader discussed how mining companies can build more resilient supply chains. He recommended an end-to-end supply chain risk assessment to prepare for global trade implications to their business.

“The first step is to review what is most critical to your operations. Find that single point of failure across the site that will really impact your operations.”

“Assessments of how much inventory will be required on-site should take into account anticipated disruption due to ongoing complexity around movement and transport. Considering alternative suppliers can ensure that a backup plan is in place.” he said.

An example of de-risking supply chain is Steel Mains, an Australian manufacturer of mild steel water pipes that operates in Victoria and Western Australia. This supplier knows first-hand about the risks faced by mines who rely on foreign supply chains.

Amir Vahdani, Steel Mains’ regional sales and mining business development manager, explains “Apart from the lower quality products and increased maintenance costs over the life of the assets, businesses that are heavily focussed on the imported products are currently at an increased delivery risk due to disruptions in the global supply chain. This will negatively impact all capital expenditure, retrofit and maintenance projects.”

For over a century Steel Mains have partnered with mining companies with a long-term view on their assets. These mining companies realise that using Steel Mains’ products lower their total cost of ownership – including capital expenditure, installation and operational costs.

The potential for a domestic manufacturing boom

The pandemic highlighted the importance of combined centralised and decentralised supply chain systems. Thereby highlighting the capacity of domestic manufacturing to de-risk supply chains.

Today’s domestic manufacturing continues to contribute to the economy, making up 6.3% of total employment (7th highest sector). Sentiment from within the manufacturing sector is also strong.

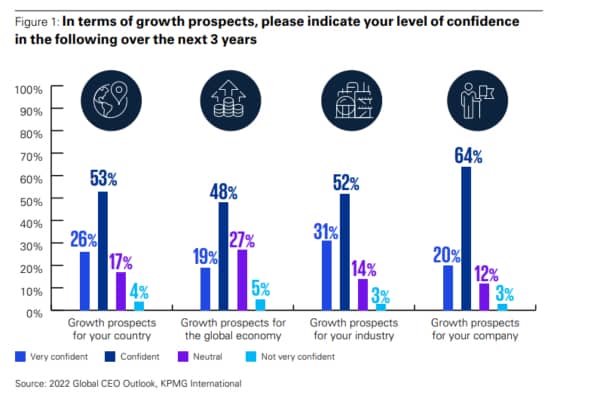

84% of manufacturing CEO’s believe their business will grow over the next 3 years.

92% of manufacturing industry leaders responded with confidence in business conditions in the next 12 months

Continued growth is expected from each manufacturing sub-industry

https://www.statista.com/outlook/io/manufacturing/australia#value-added

De-risking your supply chain requires great minds

It takes the right leadership approach and understanding of supply chain challenges for Australian businesses to succeed. For over 20 years, Occulus has provided Executive Search services in ANZ and Asia with established practices specialising within Supply Chain, which means we can focus on delivering the right C-suite talent for your business.